The KDF® Difference

KDF® Process Media vs. Activated Carbon and Silver-Impregnated Carbon

KDF® Process Media are versatile solutions for pretreatment, primary treatment, and industrial applications. Engineered to complement or replace granular activated carbon (GAC) filters, carbon block systems, and inline filters, KDF® Media dramatically extend the lifespan of GAC by protecting against bacterial fouling.

They also offer a non-toxic alternative to silver-impregnated systems, which are both costlier and classified as toxic pesticides by the EPA. Unlike silver, KDF® Media do not require EPA registration and provide a safer, more economical solution for water treatment needs.

Benefits of KDF® Process Media

-

Removes over 95% of chlorine, iron, heavy metals, and hydrogen sulfide on its own.

-

Extends carbon life when combined with granular activated carbon (GAC), lowering replacement frequency.

-

Boosts the performance and lifespan of GAC, RO, and IX systems.

-

Reduces material needs for more compact, cost-effective systems.

-

No chemical additives—100% recyclable, eliminating disposal costs.

-

Effectively controls scale, bacteria, and algae.

-

Replaces toxic silver-impregnated systems.

How KDF® Media Works

KDF®, short for kinetic degradation fluxion, isn’t just a material—it’s a breakthrough process, pioneered by water treatment expert Don Heskett in 1984. Using high-purity copper and zinc, KDF® media creates an electrochemical reaction that targets and eliminates a wide range of contaminants like iron, chlorine, hydrogen sulfide, heavy metals, and bacteria. Through a redox (oxidation-reduction) process, harmful elements are transformed—chlorine becomes harmless, water-soluble chloride and heavy metals like lead and mercury are captured on the media’s surface, effectively purifying the water.

KDF® Applications

Trusted by leading manufacturers and supporting a vast array of industries, including residential applications, hospitals, beverage producers, restaurants, and manufacturing facilities, KDF® media provides powerful protection, effectively eliminating chlorine, hydrogen sulfide, heavy metals, scale, and bacteria. Safe, efficient, and proven—it’s the go-to solution for cleaner water.

What KDF® Process Media Filters

CHLORINE / CHLORAMINE

The product removes chlorine from water through a redox reaction, where free chlorine is chemically reduced to harmless, water-soluble chloride ions. This reaction effectively eliminates up to 99% of chlorine from the water supply without the use of chemicals. The process enhances water quality, protects downstream systems from chlorine damage, and contributes to safer, more sustainable water treatment.

HYDROGEN SULFIDE

The product removes hydrogen sulfide from water through a redox reaction, where hydrogen sulfide reacts with the product's copper-zinc alloy to form insoluble copper sulfide. This compound is then easily removed through backwashing. The process eliminates the unpleasant "rotten egg" smell associated with hydrogen sulfide, providing a non-chemical, efficient solution for improving water quality.

IRON

The product removes iron from water through a redox reaction, where soluble iron ions (ferrous iron) are oxidized into insoluble ferric hydroxide. This ferric hydroxide precipitates out of the water and can be removed via regular backwashing. The process is highly efficient, achieving iron removal rates of up to 98% when sufficient oxygen is present in the water. This method is non-chemical, environmentally friendly, and extends the life of downstream water treatment systems.

HEAVY METALS

The product removes heavy metals from water through a redox reaction that causes soluble heavy metal ions (e.g. hexavalent chrome, lead, mercury, nickel, arsenic, manganese) to be reduced to their insoluble forms. These insoluble metals bond to the surface of the media, effectively removing them from the water. The process can eliminate up to 99% of heavy metals, making the water safer while reducing reliance on chemical treatments. The captured metals can also be recovered when the media is recycled.

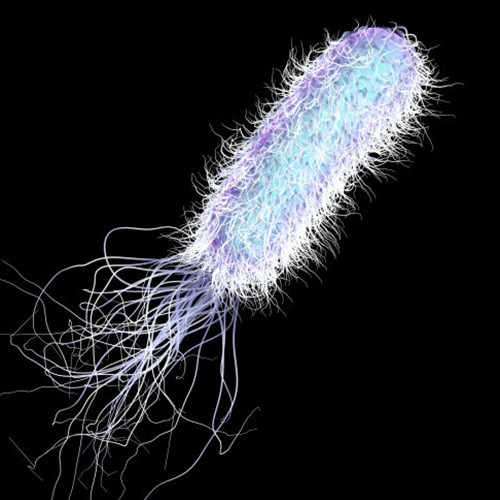

BACTERIA

The product controls and reduces bacteria in water through a combination of mechanisms enabled by its redox reaction. The copper-zinc alloy creates an environment that is toxic to bacteria by disrupting their cellular processes. This includes direct electrochemical contact, the generation of hydroxyl radicals, and shifts in oxidation-reduction potential. These processes damage bacterial cell structures and interfere with their ability to survive and reproduce, effectively reducing bacterial growth without the need for chemical additives.

SCALE

KDF® contains anti-scale capabilities, particularly KDF® 55, for water treatment applications. By effectively converting dissolved calcium (Ca²⁺) and magnesium (Mg²⁺) ions into solid precipitates, KDF® media significantly reduces water hardness and scale formation, enhancing plumbing system efficiency and overall water quality.